Shop Online

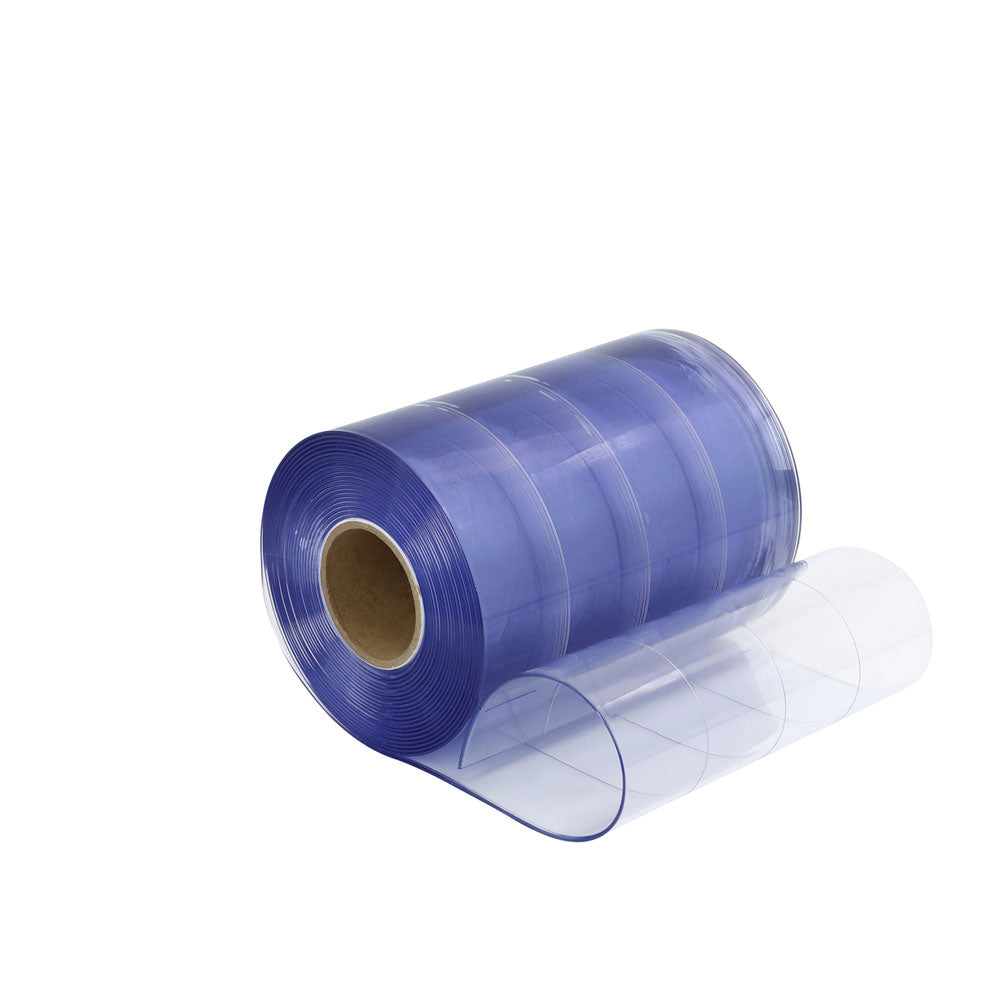

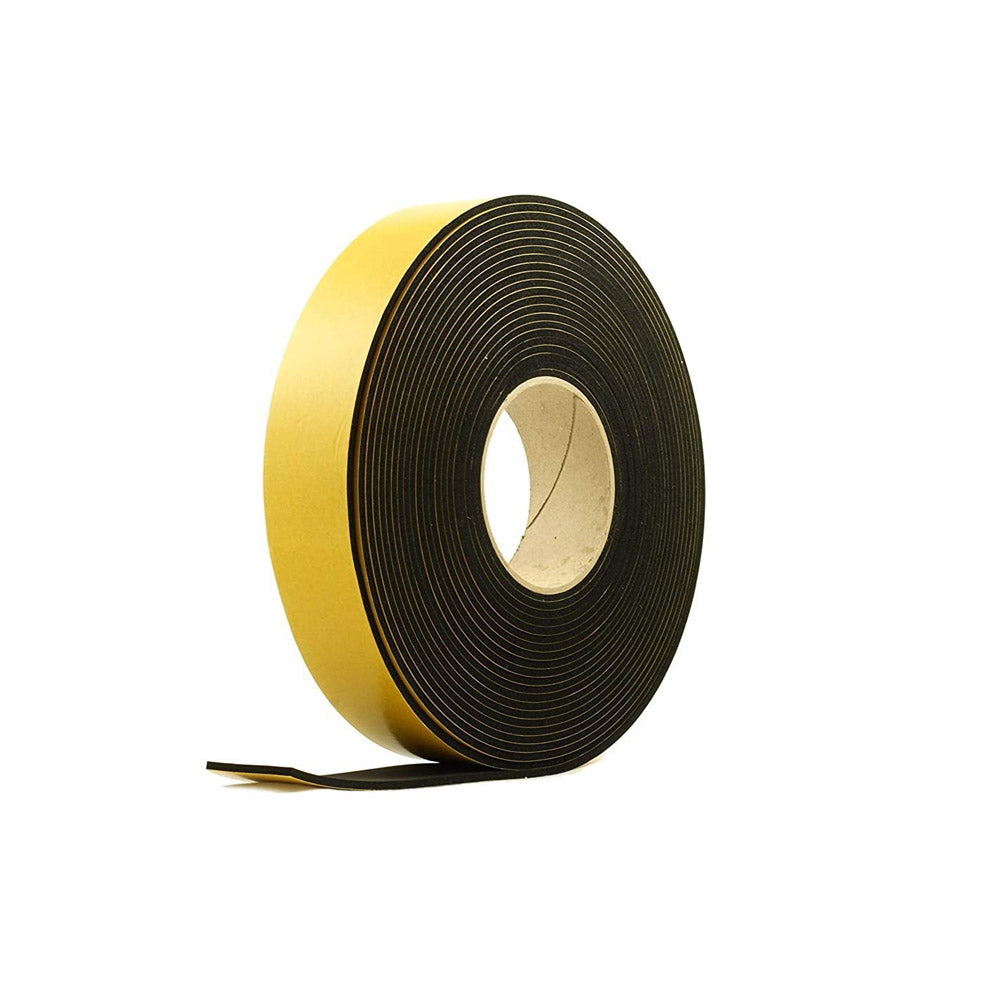

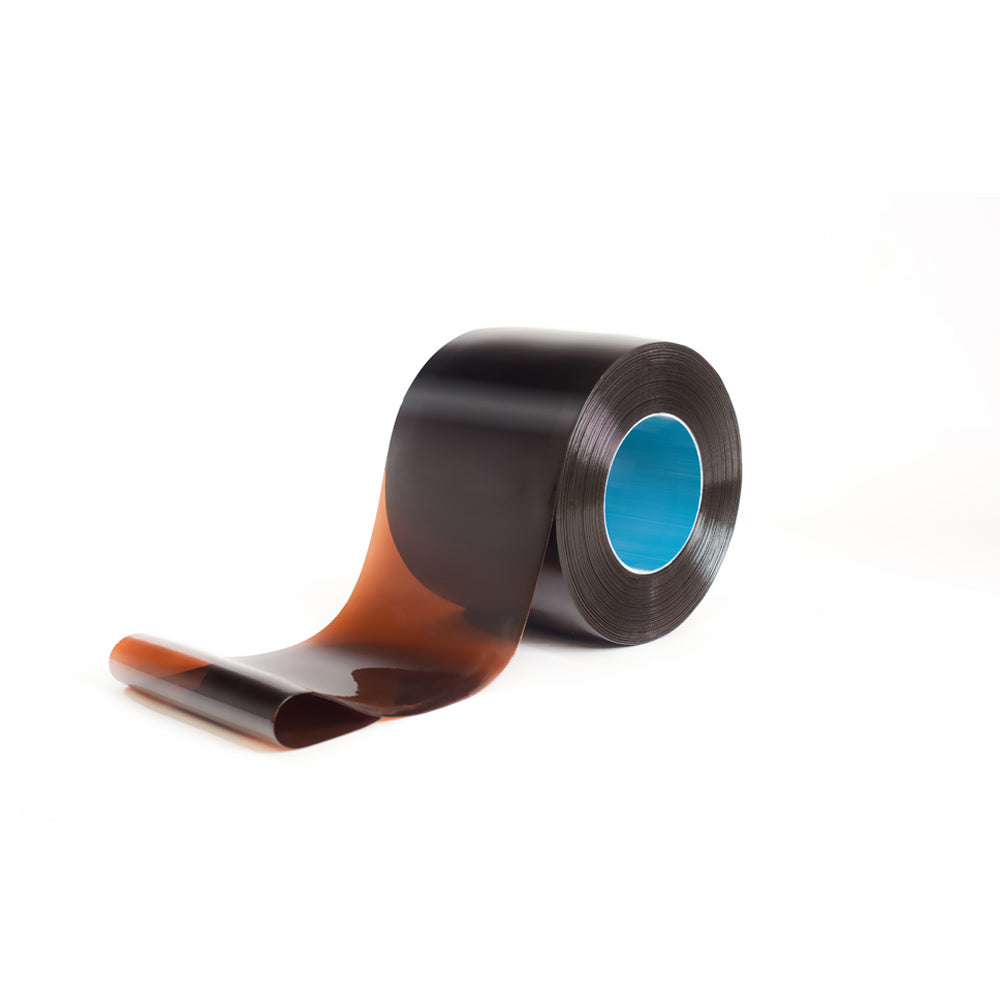

You can now order a select range of Rubberfast products online, designed to meet the needs of industrial and commercial applications.

Learn moreRubberfast Blog

View all

We are ISO 9001:2015 certified

Rubberfast has once again achieved ISO 9001:2015 certification. Validated for the next 3 years, this underscores our unwavering commitment to excel...

What is PEEK?

PEEK (or polyetheretherketone) is a strong, robust thermoplastic with excellent chemical resistance.This high performing engineering plastic has ou...

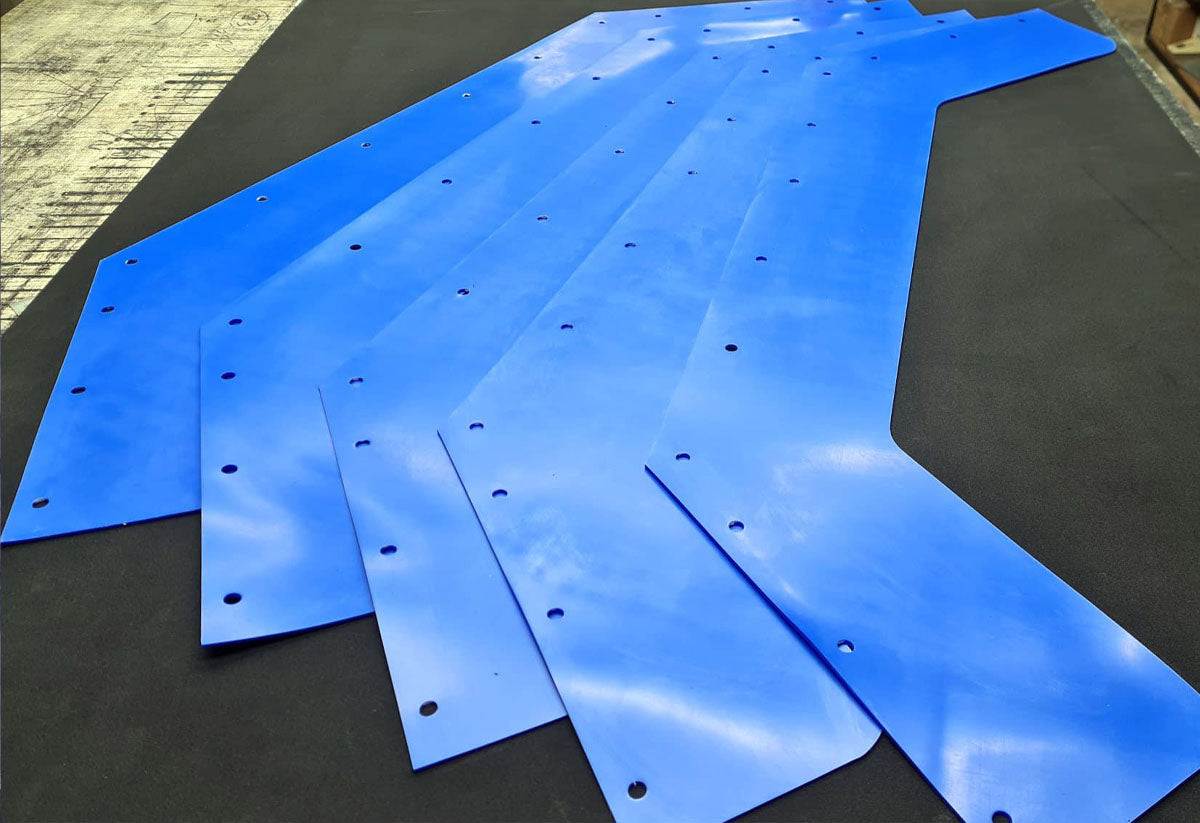

Bespoke silicone rubber gaskets

Bespoke blue silicone rubber gaskets, hand-cut to customer specification. These 'hoist' gaskets made in house, are for use in the Food industry. Th...

We are proud to be a part of the R&G Fluid Power Group

Our teams across the country are passionate about delivering first class customer service, backed up and supported by probably the largest stock-holding of fluid power products in the UK, meaning we can offer unrivalled solutions and support to our customers.

Visit Website